- New

- Sale

- Temperature

- Pressure

- Humidity

- Light Intensity & Motion

- Air Quality

- Flow

- Modbus | Wireless Modbus

- Rymaskon

- EtherCAT P

- Accessory

Carbon Dioxide CO2, Volatile Organic Compound VOC, Particulate Matter Sensors & Air Flow Monitors

AERASGARD, RHEASGARD & RHEASREG

Elevated CO2 levels, fine dust or VOC pollution in the room have a negative impact on well-being as well as energy costs. With AERASGARD® air quality sensors, CO2 transmitters, mixed gas detectors and RHEASGARD® flow sensors, you can monitor the entire indoor climate in schools, residential, work and conference rooms, cinemas, sales rooms, institutes or laboratories in a controlled manner.

With our RHEASREG® air flow monitors and flow transmitters you have air, gas or liquid carrying lines under control. For reliable flow monitoring in fans, control dampers, heating coils and humidifiers. Our sensors have a patented multi-chamber duct tube and can display up to four measured variables.

CO2 sensors

Our AERASGARD® air quality sensors offer CO2 measurement ranges of up to 5000 ppm for reliable and sustainable CO2 monitoring and control of work and living spaces, break rooms, cinemas, schools, etc. The sensors are available as tabletop, room, outdoor, duct, flush-mounted and pendant units.

Our top products from CO2 Sensors

VOC Sensoren

A ventilation system equipped with VOC sensors can optimize indoor air quality while minimizing energy consumption. Our AERASGARD® VOC sensors detect indoor air pollution from contaminated gases such as cigarette smoke, respiration, paints, cleaning agents, office supplies, bodily functions, etc.

Our top products from VOC Sensors

Fine dust sensors

Our AERASGARD® fine dust sensors are designed to protect health. The room devices reliably detect the particle concentration of the air in a size category of 0.3 to 10 micrometers by means of optical fine dust sensors.

Our top products from fine dust sensors

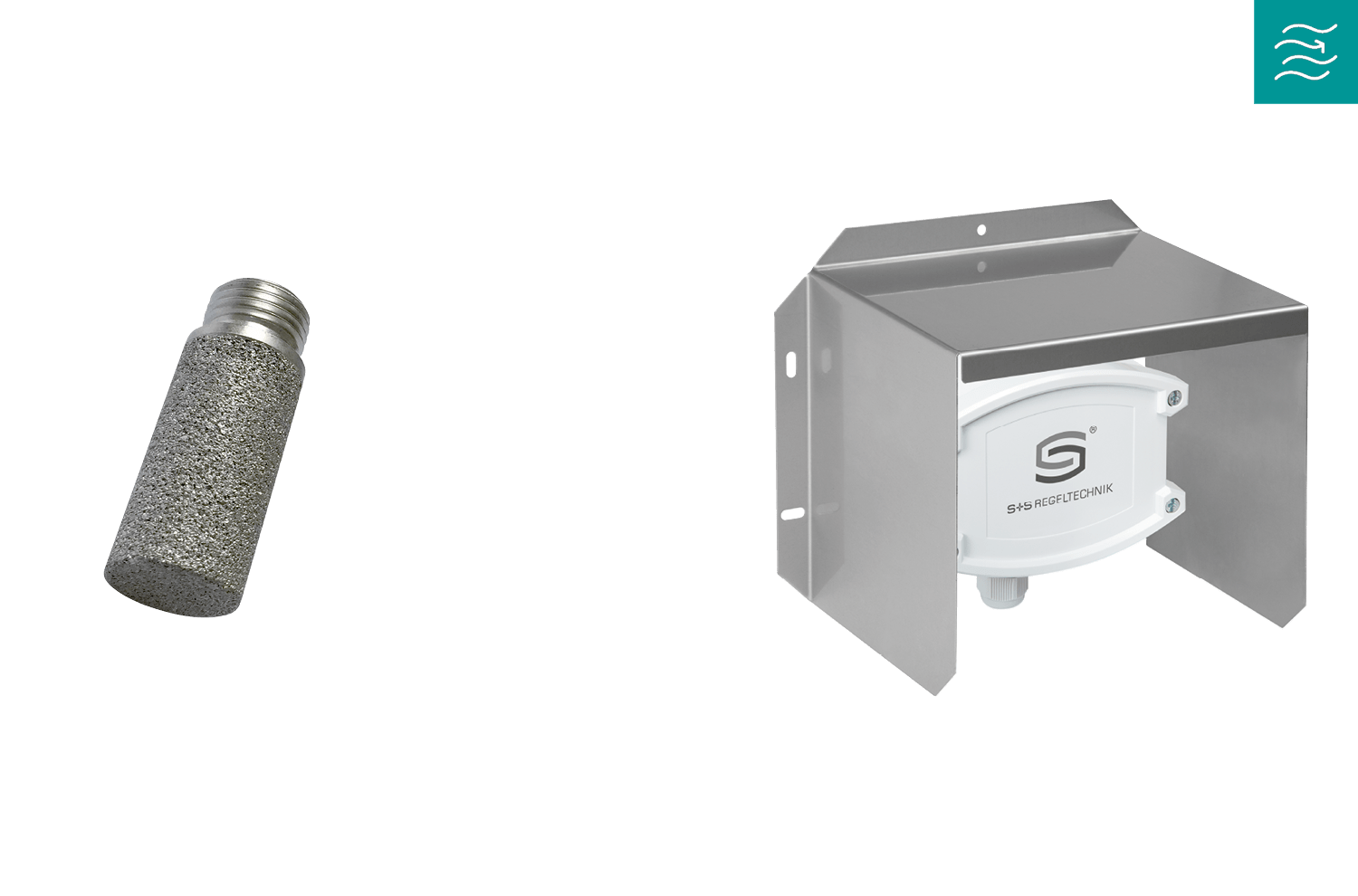

Our versatile product accessories complete the range of products and enable you to use our sensor devices easily and immediately.

For our air quality sensors, we offer you protective devices and sintered filters.

Flow monitors & airflow monitors

RHEASGARD® flow sensors are suitable for monitoring or controlling air flows in ducts, on fans, control dampers, for flow-dependent monitoring of humidifiers and electric heating coils.

Our top products from flow monitors

Flow monitors for liquid media

Our RHEASREG® flow monitors for liquid media serve as flow monitors or low-water protection, e.g. for pumps in oil and cooling circuits, refrigeration machines, evaporators, compressors and heat exchangers, in brass or stainless steel bodies.

Our top products from flow monitor for liquid media

Our versatile product accessories complete the product range and enable you to use our sensor devices easily and immediately.

For our flow monitors we offer you different devices for mounting.