- % SALE %

- Temperature

- Humidity

- Pressure

- Light Intensity & Motion

- Air Quality & Flow

- Modbus | Wireless Modbus

- PowerIO®

- EtherCAT P

- Accessory

Modbus measuring devices

What is Modbus actually?

Modbus is a communication protocol that can be used to exchange data between a master and several slaves. The protocol was developed by Gould-Modicon in 1979 to enable programmable logic controllers to communicate with each other. Instead of complex, star-shaped wiring, the Modbus protocol enables a simpler and more resource-efficient installation.

How does Modbus work?

Modbus enables a central client, such as a building management system (BMS), and several servers, for example measurement and control systems (sensors), to communicate with each other. This connection can be established via Ethernet as well as via serial interfaces such as RS232 or RS485.

Wireless transmission is also possible via Wireless Modbus/W-Modbus. With this programme, S+S Regeltechnik is the first manufacturer in the building automation and sensor technology sector to offer this programme. When communicating via Modbus, all participants must have a unique address. Communication is normally initiated by the client / building management system and the addressed server / sensor responds.

Modbus supports various operating modes, including Modbus RTU, Modbus ASCII and Modbus TCP.

Modbus

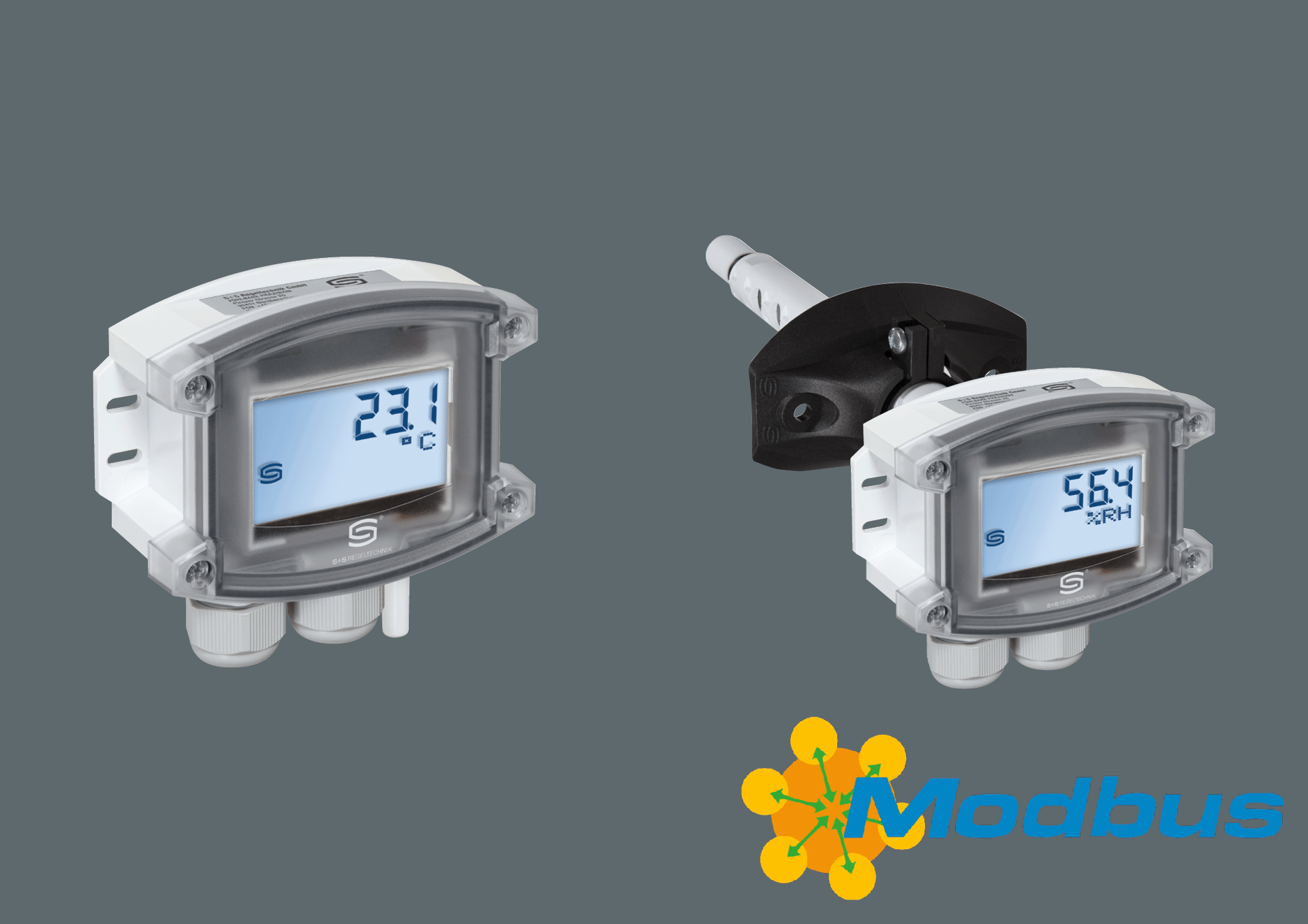

Temperature and humidity sensors

What advantages does Modbus offer?

- Very good scalability

- Cost reduction through simple installation

- No licence costs

- Modbus makes it possible to link devices from a wide range of manufacturers

- Flexible replacement or expansion

- Simple integration into an existing network

- Quick and easy troubleshooting

- Customised settings possible for each device

Modbus in building automation

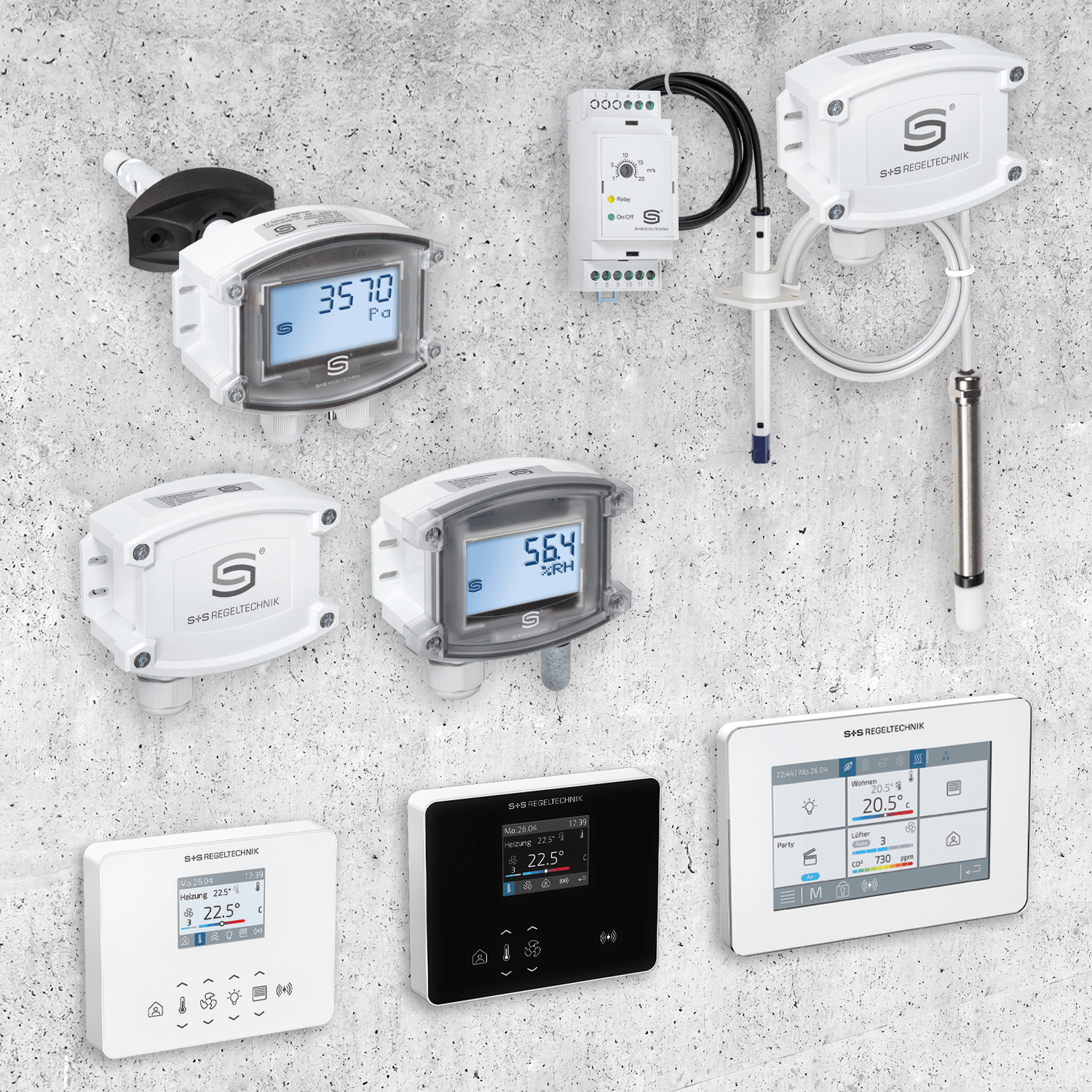

Modbus is primarily used in building automation for networking field devices and sensors with the building's automation system. Fast and simple networking of a large number of devices is possible. Modbus-capable devices are very inexpensive compared to analogue devices and therefore offer a major advantage. These price advantages are particularly important when a large number of devices are networked together.

The integration of control and regulation technology as well as the integration of heating, ventilation or cooling systems is essential for building automation. With Modbus technology, this is possible across manufacturers without the need for additional interfaces between them.

The networking of our Modbus-capable transmitters for temperature, humidity, pressure, VOC, CO2, particulate matter and air flow leads to comprehensive energy efficiency and therefore saves money.

Modbus protocols and standards

There are two main types of Modbus protocols: Modbus TCP/IP, which is used for networks that run over the TCP/IP protocol, and Modbus RTU, which is used for serial communication. Both serve the same function, but are optimised for their respective communication medium.

Modbus TCP/IP vs Modbus RTU

While TCP/IP is more suitable for network applications and enables faster data transmission over longer distances, RTU is favoured for serial communication due to its simplicity and reliability.

Modbus RTU

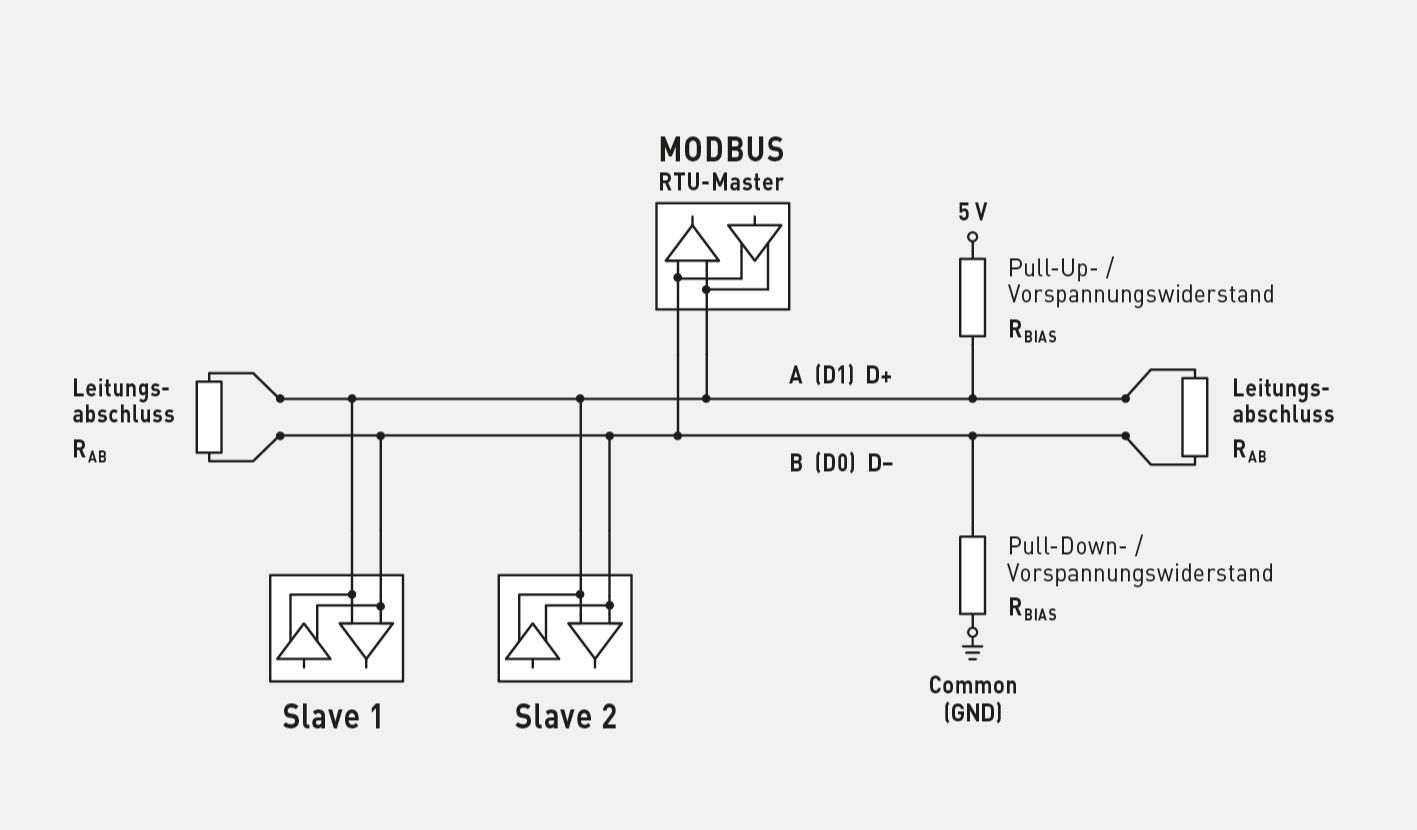

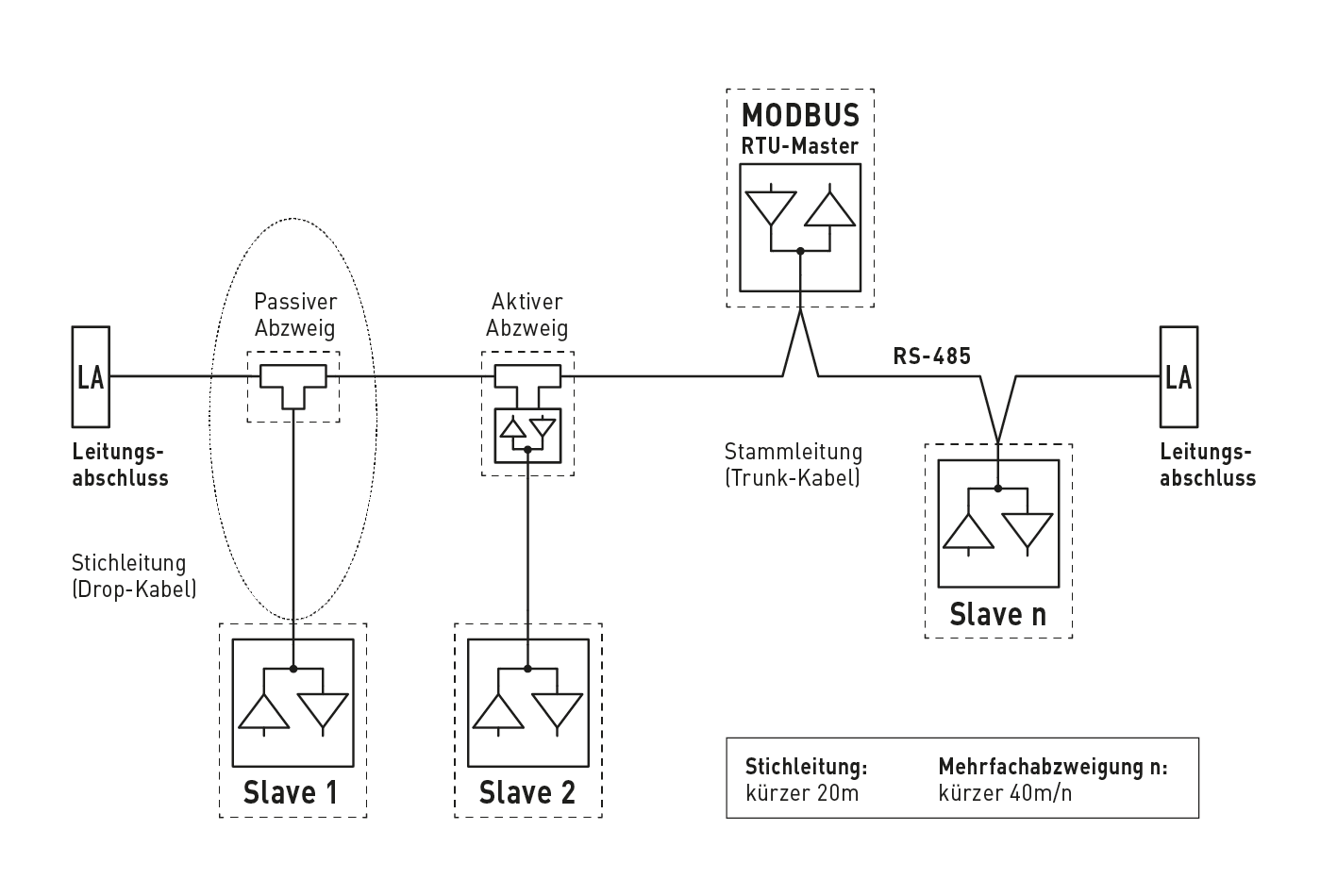

Modbus RTU (Remote Terminal Unit) is one of the most common implementations of the Modbus protocol, which is designed for serial communication and is widely used in industrial environments for connecting electronic devices. Unlike Modbus TCP/IP, which is designed for compatibility with Ethernet and TCP/IP networks, Modbus RTU is specifically tailored for serial devices and connections such as RS-485 and RS-232.

Modbus RTU is a binary protocol that provides a simple and efficient way for devices, often called slaves, to communicate with a control device, the master. It is a synchronous protocol, as each 8-bit byte in a message is sent in sequence and framed by a start and stop bit. This simple structure increases the speed of data transmission in particular, making it very effective for real-time applications.

Modbus TCP/IP

Modbus TCP/IP is an extension of the traditional Modbus protocol that allows Modbus communication to take place over a TCP/IP network. This adaptation not only preserves the simplicity and reliability of the original (serial) Modbus RTU protocol, but also enables integration into modern network architectures, making it more suitable for large-scale and Internet-based applications.

Basically, Modbus TCP/IP uses the same model as the classic Modbus, namely a client-server (or master-slave) model. However, unlike Modbus RTU, which transmits data via serial connections, Modbus TCP/IP does so via TCP/IP networks. This means that it uses Ethernet connections and can be forwarded via the Internet.

Modbus ASC II

Modbus ASCII (American Standard Code for Information Interchange) is another variant of the Modbus protocol for serial communication that encodes data as ASCII characters, as opposed to Modbus RTU, which encodes data in binary. Modbus ASCII is particularly useful in environments where data transparency and readability take precedence over data transmission speed.

Modbus ASCII represents each byte of data as two ASCII characters, which increases the size of the message packet but makes monitoring and troubleshooting easier as the contents of the packet can be read without the need for specialised software to decode it. This can be particularly useful for troubleshooting and in training environments, where understanding the data flow can help to diagnose problems more quickly.

Eliminating faults in the network - is that possible?

Troubleshooting is extremely easy with Modbus systems. The integrated error diagnosis function can be used to call up the error status via the bus query and determine the exact error point in the system. Apart from this, the bus cables should always be checked for faults or loose connections first.

Device variants with a display are particularly user-friendly: in the event of a fault (e.g. communication interrupted), the display shows a plain text diagnostic message. This means that the current status of the device can be found out immediately. This saves an enormous amount of time and money.

Can I buy Modbus sensors from S+S Regeltechnik?

S+S Regeltechnik GmbH recognised the advantages of Modbus for building automation at an early stage and offers all sensors and field devices as Modbus versions.

Our measuring devices provide reliable and accurate measurement data that enables precise control and optimisation. Get an overview of our Modbus product range now. Whether you need transmitters for building automation, HVAC or process technology, we have the right product for you.

Benefit from our cost-effective solutions without compromising on quality. We offer you all items relating to sensors and field devices from a single source, because we know how important competitive pricing is. Our range goes beyond the standard portfolio and is therefore the perfect choice.

By the way: Modbus products from S+S are also compatible with products from other manufacturers. Existing networks can therefore be easily expanded or replaced with our devices.