- New

- Sale

- Temperature

- Humidity

- Pressure

- Light Intensity & Motion

- Air Quality

- Flow

- Modbus | Wireless Modbus

- Rymaskon

- EtherCAT P

- Accessory

Differential Pressure Switch

Our differential pressure switches are used for monitoring positive, differential, and negative pressures in air ducts, supply or exhaust air units, and for tasks such as filter and flow monitoring, as well as controlling fans and air dampers or acting as limit controllers.

These switches support a wide range of applications thanks to their DDC-compatible, potential-free, gold-plated changeover contacts and are straightforward to install with their included mounting kits. Designed to perform reliably in temperatures from -30 to +85 °C / -22 to +185 °F and in humid environments of up to 90% RH, our switches ensure optimal functionality across diverse settings.Learn about differential pressure switches

Differential pressure switch from S+S Regeltechnik

Our sensor devices are manufactured directly in Nuremberg, Germany and meet the highest quality standards. Our differential pressure switches are designed for a wide range of applications, ensuring reliable monitoring of air pressures in various environments. Whether it's for HVAC systems, clean rooms, or industrial settings, our PREMASREG® DS series stands out with robust features that enhance both performance and reliability.

What is a differential pressure switch?

A differential pressure switch monitors and reacts to the difference in pressure between two points, commonly used in air ducts or between environments to ensure proper air flow and filtration.

What does a differential pressure switch do?

A differential pressure switch is a device that monitors and responds to the difference in pressure between two points. It's used to control and ensure proper functioning in various systems by detecting if the pressure difference reaches a predetermined point.

What is the difference between a differential pressure switch and transmitter?

The difference between a differential pressure switch and a differential pressure transmitter lies in what they do with the pressure information they detect:

The differential pressure switch acts like a light switch, turning on or off when the pressure difference between two points reaches a set threshold. The differential pressure transmittert provides continuous measurement and detailed data for more sophisticated process control. The output signal is usually 0-10V, 4-20mA or Bus (e.g. Modbus, Wireless Modbus or EtherCAT P)

Differential pressure switch

Differential pressure transmitter

Applications

- Air Filter Monitoring:

Differential pressure switches can detect when filters become clogged with dust and debris. A clogged filter increases the pressure drop across it, and when this drop reaches a preset threshold, the switch can trigger an alarm or system response to indicate that the filter needs cleaning or replacement. - Fan Control:

These switches are used to monitor the operation of fans. They can ensure that fans are operating correctly by detecting the pressure difference caused by the fan’s operation. If the pressure difference is too low, it might indicate a fan failure or malfunction, prompting maintenance. - Duct Pressure Monitoring:

In large HVAC systems, maintaining correct pressure within ductwork is crucial for efficient airflow. Differential pressure switches can help maintain this by monitoring the pressure in different sections of the ductwork and adjusting system controls as necessary. - System Interlocks:

These switches can serve as safety interlocks. For example, they can ensure that certain parts of the HVAC system, such as heaters or coolers, only operate when the fan is functioning properly, preventing overheating or inefficient cooling. - Fire and Smoke Control Systems:

In the event of a fire, it's crucial to control the spread of smoke through HVAC ducts. Differential pressure switches can activate smoke dampers, which close to prevent the spread of smoke through the building. - Variable Air Volume Systems (VAV):

In VAV systems, the airflow rate is varied based on the demand. Differential pressure switches can monitor the pressure in these systems to control the air volume supplied to different areas, optimizing energy use and maintaining comfort.

Modbus

Temperature and humidity sensors

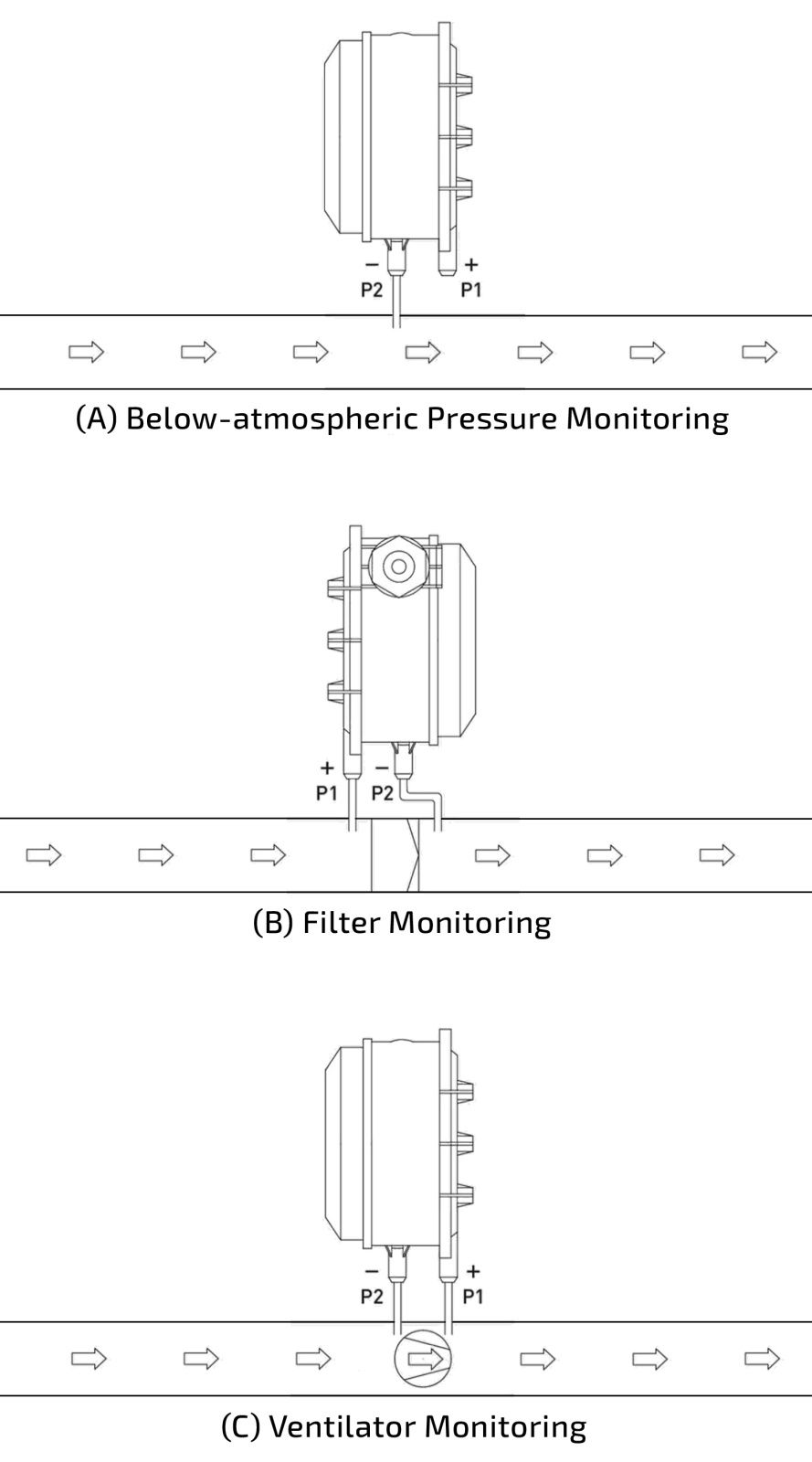

Types of monitoring - How to mount the differential pressure switch for a specific purpose

Differential pressure switches have different types of how they can be installed. The pictures shows 3 different approaches of installing them. Below you will find a short description of each application with an example.

- Below-atmospheric Pressure Monitoring (A):

This type is used to measure negative pressures relative to the ambient atmosphere. For instance, in a clean room or a scientific laboratory where maintaining a precise negative pressure environment is crucial to prevent outside contamination, the differential pressure switch (P2) is connected internally to the room, while the reference side (P1) is left open to the atmosphere. The switch can signal an alert if the negative pressure drops, indicating a breach in room integrity. - Filter Monitoring (B):

For maintaining air quality and ensuring efficient operation of HVAC systems, the differential pressure switch is installed with port P1 upstream of an air filtration unit and port P2 downstream. This configuration is typical in HVAC systems to detect when filters accumulate particulates and cause a pressure drop, which could impede airflow. The switch triggers when the pressure drop exceeds the acceptable range, indicating that the filter requires cleaning or replacement. - Ventilator Monitoring (C):

In applications for example in underground transit systems or industrial ventilation, ensuring that ventilators are effectively moving air is paramount for air quality and safety. The switch is set up with port P1 downstream of the fan, measuring the discharged air pressure, while port P2 is positioned upstream to measure the intake pressure. The differential pressure switch continuously monitors the operational efficiency of the ventilator by observing the pressure differential it produces. If the pressure differential falls below a certain threshold (triggering the switch), it may signal a fan malfunction or degradation, prompting inspection and maintenance.